3 Reasons Why a Robotic Arm is Better Than a Jib

By Paddy Taylor – Head of Broadcast, MRMC.

By Paddy Taylor – Head of Broadcast, MRMC.

One of the recurring points of discussion that has come up during some of the recent demos of our broadcast studio products has been from customers who currently own a jib, asking if I own a jib, why would I even think about using a robotic arm? Well, before I get into that question today it’s probably best to think about what a camera jib or crane are used for. In a studio, the jib’s main job is to provide interesting motion during your production. It creates a variety of high or low shots or lateral movement making some subjects seem more interesting or in other cases, it adds a level of dynamism that is impossible to achieve through handheld, tripod, or dolly/pedestal-based cameras. A key advantage of a camera jib is that they are extremely simple to use and also pretty low-cost, so you get a lot of interesting movement for not a lot of money. So whilst a jib can very effective, we would argue that a robotic arm has a number of key advantages over a jib, which we will go through in the 3 key points below:

Reason 1 - Reduced Footprint

A significant issue with a Jib is the amount of space they take up. To be able to create the type of movements that they do you need to have a lot of space behind the arm for the cantilever to lift the camera into different positions. This requires a lot more space than just the immediate studio area and may mean a compromise on the size of the jib or that it simply won’t fit. Added to this the simple design of a jib coupled with the desired reach and moves means that the more weight you add to the arm the harder it is to move and to maintain smooth and accurate moves so the payload on the jib is limited.

The footprint of the robotic arm is much smaller. It can take up a third of the space of a similar capability jib. The robotic arm is also more flexible it can be mounted in a number of different ways, a fixed base on the floor or ceiling or a track again floor or ceiling mounted.

A significant issue with a Jib is the amount of space they take up. To be able to create the type of movements that they do you need to have a lot of space behind the arm for the cantilever to lift the camera into different positions. This requires a lot more space than just the immediate studio area and may mean a compromise on the size of the jib or that it simply won’t fit. Added to this the simple design of a jib coupled with the desired reach and moves means that the more weight you add to the arm the harder it is to move and to maintain smooth and accurate moves so the payload on the jib is limited.

The footprint of the robotic arm is much smaller. It can take up a third of the space of a similar capability jib. The robotic arm is also more flexible it can be mounted in a number of different ways, a fixed base on the floor or ceiling or a track again floor or ceiling mounted.

REASON 2 – IMPROVED ACCURACY & REPEATABILITY

A robotic arm is also more accurate and repeatable, a camera jib can create a similar type of shot but you’re relying on the accuracy of the operator to be able to repeat this. With a robotic arm, you will always get exactly the same shot all of the time. The multiple axes (up to 9) provide motion that isn’t possible with the typical 4-5 axes of a jib or crane.

A robotic arm is also more accurate and repeatable, a camera jib can create a similar type of shot but you’re relying on the accuracy of the operator to be able to repeat this. With a robotic arm, you will always get exactly the same shot all of the time. The multiple axes (up to 9) provide motion that isn’t possible with the typical 4-5 axes of a jib or crane.

REASON 3 – A MORE COST-EFFICIENT OPTION

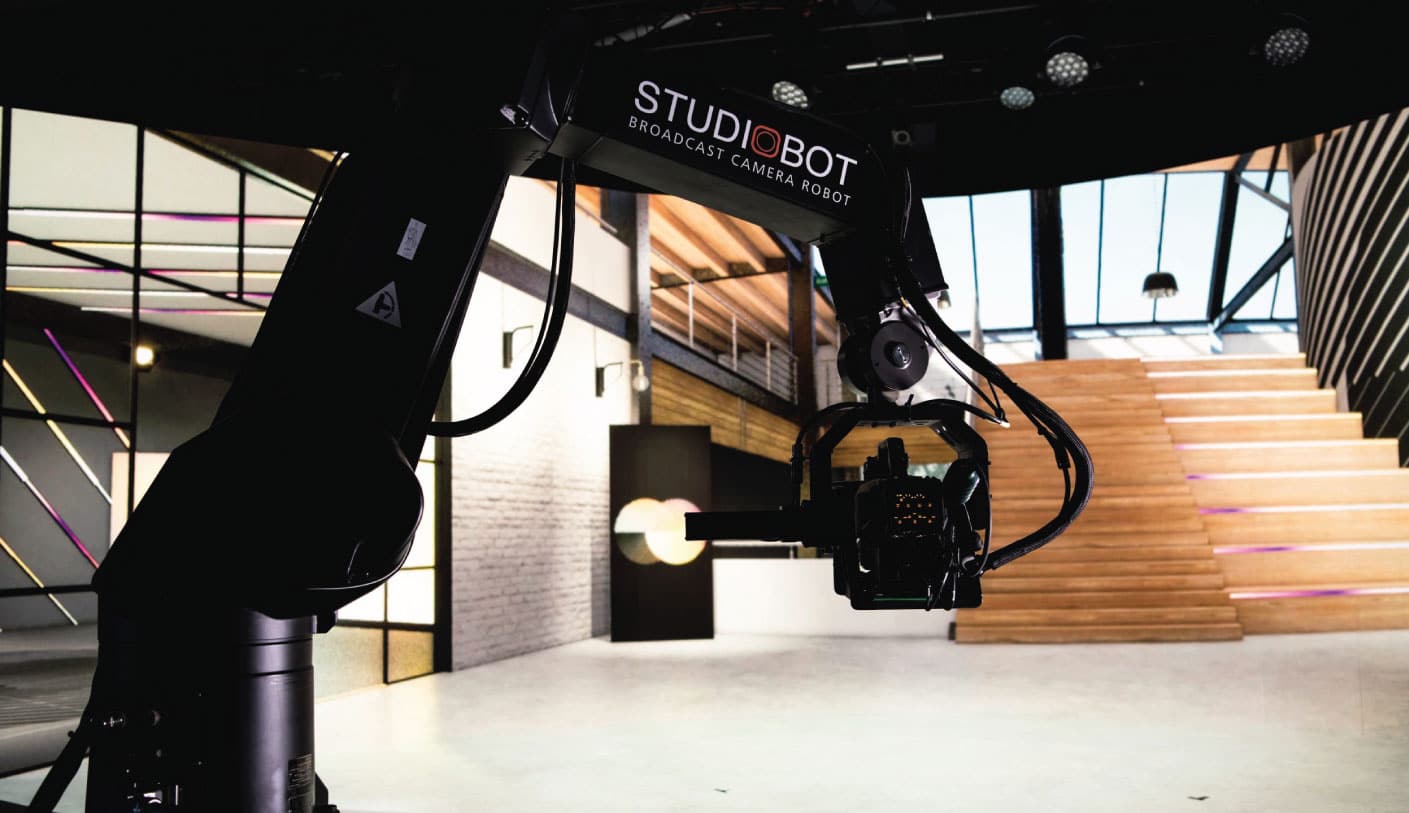

An important consideration is cost; which is cheaper? A cheap camera jib could start at £10000 depending on its length requirements, payload etc up to maybe £30-£40,000 for a large unit (you could spend a lot more on a really big unit). Robotic arms typically start around £50,000 and can cost well over £200,000. A typical arm like our StudioBot which would give you a height of up to 2.35m (it can go a lot higher depending on the base) and a number of different mounting options would be around £100,000. The key factor is operating costs versus purchase costs. the camera jib will be cheaper to purchase however there will usually be more expensive to run.

The first consideration is whether or not you need an operator for a robot. You always need an operator for a jib. In most robotic arm scenarios you can create movement in advance and recall these presets creating sequences or journeys within your studio. These can be either recalled simply using a controller so any other job function in the studio can undertake this function or they can be controlled through automation so these predefined moves are just triggered using event scheduling as part of the studio automation. System such as Ross overdrive, VizRT Mosart, Grass Valley Ignite provide this sort of functionality but they’re also simple are cheaper options to replicate this function without having to connect to more complex other solutions within the studio.

Let’s consider a few different scenarios if you’re only running a show once or twice a week and want some interesting movement a camera jib at £20,000 is probably a really good investment. The cost of the operator for the jib would probably only be £100-£200 depending on the length of the shift required

If you’re running more than 1 show a day then robotic arm is cheaper than a jib. The significantly lower cost of running a robotic arm like the Studiobot or Studiobot XL means that they can pay for themselves in months where as the jib will have the continuing operator costs. On top the cost savings you have the advantage of the robot always being available, lower carbon footprint as staff don’t need to travel in and all the production improvements of repeatability, accuracy, synchronising multiple arms (this can create some amazing moves and can’t be done reliably with jibs)

An important consideration is cost; which is cheaper? A cheap camera jib could start at £10000 depending on its length requirements, payload etc up to maybe £30-£40,000 for a large unit (you could spend a lot more on a really big unit). Robotic arms typically start around £50,000 and can cost well over £200,000. A typical arm like our StudioBot which would give you a height of up to 2.35m (it can go a lot higher depending on the base) and a number of different mounting options would be around £100,000. The key factor is operating costs versus purchase costs. the camera jib will be cheaper to purchase however there will usually be more expensive to run.

The first consideration is whether or not you need an operator for a robot. You always need an operator for a jib. In most robotic arm scenarios you can create movement in advance and recall these presets creating sequences or journeys within your studio. These can be either recalled simply using a controller so any other job function in the studio can undertake this function or they can be controlled through automation so these predefined moves are just triggered using event scheduling as part of the studio automation. System such as Ross overdrive, VizRT Mosart, Grass Valley Ignite provide this sort of functionality but they’re also simple are cheaper options to replicate this function without having to connect to more complex other solutions within the studio.

Let’s consider a few different scenarios if you’re only running a show once or twice a week and want some interesting movement a camera jib at £20,000 is probably a really good investment. The cost of the operator for the jib would probably only be £100-£200 depending on the length of the shift required

If you’re running more than 1 show a day then robotic arm is cheaper than a jib. The significantly lower cost of running a robotic arm like the Studiobot or Studiobot XL means that they can pay for themselves in months where as the jib will have the continuing operator costs. On top the cost savings you have the advantage of the robot always being available, lower carbon footprint as staff don’t need to travel in and all the production improvements of repeatability, accuracy, synchronising multiple arms (this can create some amazing moves and can’t be done reliably with jibs)

If this improved workflow is of interest, but the advantage to you of a jib or crane is that you are paying for it over time out of operating expenses, then we can help with our very competitive finance rates and lease options.